UFO Dual Chamfer Insert - 3T

3T Series

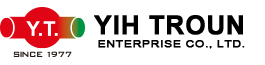

The UFO dual chamfer insert, also known as positive-negative chamfer insert or double-sided chamfer insert, is mostly used to remove burrs around the hole after drilling, with the front and back chamfering in a single pass, efficiently and accurately for excellent solutions.

The diameter of the UFO dual chamfer insert is as small as Ø 9.8 - Ø 14.8, capable of removing the burrs of D10 holes at the top and bottom edges, and the 4-tooth blade provides very high machining efficiency.

Features

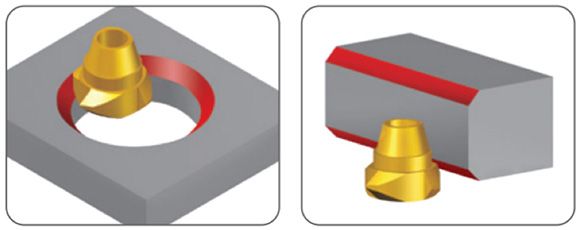

- Suitable for chamfering the hole at the top and bottom edge of the workpiece in a single pass, and also for chamfering the side edge angle.

- The high accuracy of insert center positioning increases the tool life and machining precision.

Specification

- Full series diameters: Ø 9.8 - Ø 14.8 mm (effective machining with 4 teeth)

- Applied angle: 45 degrees

- Applicable for top and bottom chamfering edge in one go.

- Movies

- Catalogue Download

-