-

UFO Carbide Common Toolholder - CB3W

CB3W Series

In long overhang machining, carbide shank provides relatively better stability and enhance the tool life of the insert than HSS shanks, despite it is always more expensive, but at the same time carbide shank improves the vibration resistance and the durability. Whether it is used in T-slot insert or in thread milling insert, it is recommended to use carbide shank to reduce the cost by more than 50%. Different shank can fit in different dia. of inserts from 10 - 80mm and other inserts in 11 different profiles.

-

UFO T-slot Insert - 3T

3T Series

The tapered-polygon-interface is made by complete-grinded processing to keep the lowest tolerance of connect positioning ± 0.01mm and optimize machining accuracy and insert life. Min. thickness of insert starts from 0.5mm, the whole range of insert dia. from 10 ~ 32 mm. In small thickness, we stock every 0.1mm as standard item in stock. In complete range of specifications and great performance in chip evacuation, Y.T. UFO T-slot cutter is always the best choice for small slot application. In the whole series of UFO family, besides UFO T-slot insert, there is other inserts such as UFO Thread milling / UFO chamfer / UFO radius insert… etc., all can fit in common shank if it's in the same size. For the purpose of improve accuracy and tool life by decrease cutting resistance, YIH TROUN features spiral staggered teeth on the UFO T-slot cutter which with thickness above 1.5mm and in coating grade for processing steel materials.

-

UFO T-slot Cutter - 3T / 3TS

3T / 3TS Series

YIH TROUN provides three types of T-slot cutter in bigger size 1. Series 3T16 and 3T25 in LNGT insert: diameter Ø 32, Ø 35, Ø 40, Ø 50, Ø 60, Ø 80; thickness 1.4mm ~ 8mm. This LNGT insert is designed by a patented screwless grip-type structure, it was clamped firmly and provides an excellent performance during an extreme test on 17,500rpm. 2. Series 3TS25 in SNGX / SNGW insert: Diameter Ø 50, Ø 60, Ø 80; thickness 4mm ~ 12mm. The square type SNGX insert is focus on a thicker range, it was designed with 4 cutting edges and performs greater cost effectiveness compare to LNGT. Meanwhile the cutter can also fit SNGW insert, which has radius edge: R0.4 / R0.8 / R1.2 / R1.6 / R2.0 / R2.5 / R3.0, it can be applied in machining at the edge of the slot to strengthen the structure. Same insert can be fitted on both left and right side of the cutter.

-

UFO T-slot Cutter (Fit round insert) - 3TR

3TR Series

T-slot cutter in radius slot with round insert Series 3T2560-R: diameter Ø 60, Ø 80; thickness 8mm, 10mm, 12mm. YIH TROUN offer an alternative T-slot cutter fits the round insert which is exclusively solution for grooving full radius. Radius size: R4 / R5 / R6

-

UFO Thread Milling Insert (Full Profile) - 3T

3T Series

The UFO thread milling cutter (full profile) provides a different choice from the market. General thread milling tool start with larger-diameter and fewer no. of teeth, resulting in limited application and low efficiency. YIH TROUN UFO full partial profile thread milling insert has a minimum diameter of 10mm with 4 teeth, along with three threading angles: ISO / UN / BSW. The full profile insert can do machining of several pitches in a single pass, coupled with shanks of different length.

-

Spot Drill Insert - 23 - 90°

23 Series

YIH TROUN Spot Drill features sandwich plug-and-clamp construction as well as special design with tapered key. It stays eccentricity ± 0.008mm, approaches almost zero eccentric in stationary status. A precise spot drill helps in great saving of tap breakage. Special carbide grade C350 / B350 has great strength on insert cutting edge especially in the condition of high feed machining, with it's 2 effective cutting edges, the machining efficiency increased dramatically 300% - 1000%. Multifunctional purpose can be used in spot positioning, round-hole chamfering, side corner chamfering, V-shape grooving and engraving.

-

Spot Drill Insert - A23 - 90° / 142°

A23 Series

YIH TROUN Spot Drill features sandwich plug-and-clamp construction as well as special design with tapered key. It stays eccentricity ± 0.008mm, approaches almost zero eccentric in stationary status. A precise spot drill helps in great saving of tap breakage. The spot drill features two cutting angles, it preforms 45° chamfering and 142° spot positioning in single pass. It helps customer in saving one extra procedure and tool cost.

-

Center Drill Insert - C24 - 90°

C24 Series

Center Drill 90 & deg; (type-C): When using a drill which size is smaller than the upper chamfering hole, this center drill helps making a center positioning hole and chamfering in single pass prior to drilling and tapping, no extra chamfering process required.

-

Center Drill Insert - D24 - 60°

D24 Series

Center Drill 60 & deg; (type-D): This indexable center drill is a unique item which was designed with a shorter drill bit in regular angle 60°, exclusively applicable for the tiny drilling and tapping. It offers good value and tool life even 3 times more than above types.

-

CBK / HBM / CBI Series

CBK / HBM Series

Indexable counter bore exclusively used for drilling machine uses patented carbide stripe design. This solves the issue that front guiding head is worn out due to collision inside of hole during machining process. Carbide insert with extremely high value has four cutting edges available. It is more valuable than high-speed steel regarding machining cost. HBM holder design can connect with Morse taper arbor and extension shank to meet the requirements of working machine installation.

-

Chamfer King - HCI

HCI Series

By using patented carbide stripe design, no burrs generated at chamfer even using on instable drilling machine. Manufacturers don't need to regrind cutting edges each time; they only need to replace insert. Carbide grinded insert can accomplish machining on all materials. One insert has two cutting edges applicable. Average cost for single cutting edge is even cheaper than high-speed steel. Max. outer diameter with chamfer of HCI series is up to 110mm. The length of carbide insert up to 40mm is used and can reach very long chamfer edge length without step line issue. Meanwhile it covers wide range of chamfering depth. Connector with screw-in type design can be equipped on: side lock holder, Morse taper arbor and BT arbor.

-

UFO MILL Common Holders (HSS) - BB3

BB3 Series

Compared with steel shank holder, BB3 has better stability as it’s made in HSS material. Advantages: 1. HSS tool holder is less expensive than carbide shank, yet the performance is already good enough in general machining. It’s unique capto connection design can firmly and closely combine the tool holder and the carbide head. 2. Improves the surface finishing. 3. Improve dimensional accuracy. 4. Suitable for shallow overhang machining. 5. Five kinds of tool holder options, combined with different designs of carbide heads, which are widely used in various industries.

-

UFO MILL Common Holders - BB3W

BB3W Series

UFO carbide tool holder has excellent anti-vibration effect, which can prolong the tool life in mass production and machining, it is especially suitable for application in long overhang machining. Advantage: 1. The carbide tool holder has excellent anti-vibration effect, it’s unique capto connection design can firmly and closely combine the tool holder and the carbide head. 2. Improves the surface finishing. 3. Improve dimensional accuracy and milling speed. 4. Suitable for large overhangs and batch machining

-

UFO MILL Carbide Milling Head - 3B

3B Series

Indexable UFO carbide milling head 3B series, the cutting edge angle and thickness are more optimized, and the classification of insert geometry is more refined. The milling head is divided into three geometries: M, ME, E, it applies for different materials. - M geometry is for steel / hardened steel / cast iron - ME geometry is for steel / white iron / titanium alloy - E geometry is for non-ferrous metals such as aluminum / copper The corner radius is variant from R0, R0.5, R1.0, R1.5, R2.0. Combining UFO milling heads with 5 kinds of high-speed steel tool holder and carbide tool holder designs will have more than thousands types of milling tool size. It provides more choices to cover various angles and width of cutting in different workpieces and machining conditions/ applications. Advantage: 1. The patented CAPTO positioning design further improves the tightness and stability of the tool holder and the milling head. 2. The finish surface of the milling is distinguished. 3. Precision grinding of outer diameter and the Radius has excellent dimensional accuracy. 4. Suitable in long overhang machining 5. Fully grinded carbide head achieves excellent tool life 6. Combining UFO heads with 5 designs of high-speed steel and carbide tool holder turns out thousands of milling applications in different size and workpiece materials, which are widely used in machining parts in various industries.

-

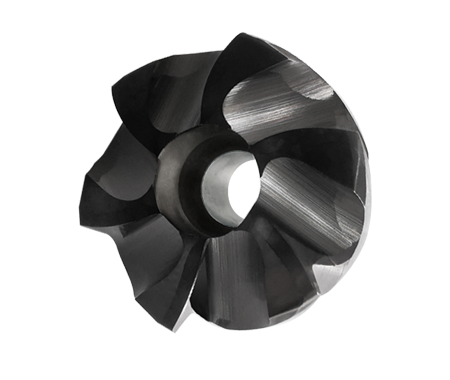

UFO MILL High Feed Mill - 3BH

3BH Series

UFO high-feed milling head 3BH series with 4, 5, 6, flutes and unique design of arc and point contact. It is effective in keeping the radial force lesser than axial force. The cutting force is transferred to the spindle, it brings machining process in stable conditions and carries out a high removal rate. A variety of special cutting angles can reach 3 times the speed of other milling tools while milling, and the ultra-high milling feed can greatly reduce the machining time and optimize the value. Advantage: 1. The patented CAPTO positioning design further improves the tightness and stability of the tool holder and the milling head. 2. The special geometric design reduces friction and leads to an efficient high feed machining. 3. Suitable for a wide range of applications in aerospace, medical and automotive industries. 4. Fully grinded carbide head achieves excellent tool life 5. UFO high feed’s multi-flutes and arc design achieves 3 times faster than ordinary milling tool.

-

UFO MILL High-feed Chamfer Milling Head - 3BC

3BC Series

YIH TROUN’s indexable high-feed chamfer milling head of 3BC series, with it’s multi-flutes in 5, 7, 9 flutes and optimal cutting angle design, can achieve 3-5 times faster than the other chamfering cutters on the market. The chamfering angles are available in 30°, 45°, 60°, and all applicable in outer and inner chamfering. 3BC chamfer milling head can be fitted with 5 types of HSS/ carbide tool holder. Additionally the universal carbide grade B100 is applicable in all kind of materials, such us stainless steel, steel, cast iron, aluminum. In small chamfer milling can reach ultra-optimized high feed rate and result in a great reduction of machining time. Advantage: 1. The carbide tool holder has excellent anti-vibration effect, it’s unique capto connection design can firmly and closely combine the tool holder and the carbide head. 2. Improves the surface finishing. 3. Improve dimensional accuracy and milling speed. 4. Multi-flutes carbide head design can reach optimal high feed rate. 5. One carbide grade can be used in machining different kinds of materials.

- Home Homepage

- Profile Company Profile

- Products Product Category

-

News Event and News

- Annual Y.T. Corporate Exhibition 2024

- 2023 METALEX

- 2023 EMO HANNOVER

- TIMTOS 2023

- AMB International Metalworking Exhibition

- The success of the researchment in metal cermet insert

- Vietnam branch office set up

- New design modification : engraving / chamfer king /center drill

- TIMTOS Online 2021

- MANUFACTURING INDONESIA 2018

- EMAF 2018

- 2018 Taiwan International Machine Tool Show (TMTS)

- JIMTOF 2018 The 29th Japan International Machine Tool Fair

- Manufacturing Technology Expo, Semarang 2018

- Manufacturing & Machine Tool Surabaya 2018

- India’s Premier International Machine Tools Show 2018

- BIEMH 2018

- Metaltech Malaysia 2018

- China Changzhou International Industrial Equipment Fair 2018

- Bangkok, Thailand MTA 2018

- Yantai Intemational Equipment Manufacture Industry Exhibition 2018

- The Exhibition of Lijia Internation Machinery 2018

- Metal Equipment Tools Lviv VIII specialized exhibition 2018

- China CNC Machine Tool Fair-CCMT 2018

- SUZHOU International Industry Expo- SIIE 2018

- Italy MECSPE 2018

- Konepaja Messut 2018, Finland

- TechniShow 2018- Utrecht, Netherlands

- Tianjin International machine Tool Exhibition-IMEX 2018

- Spot drill precision to reduce problems of drills and taps breakage

- New Member in the UFO Family ~ UFO Dovetail Cutter

-

Solution Q & A

- How to reduce the machining cost in hole making

- UFO thread milling insert _ partial and full profile

- Indexable Circlip and Radius insert

- Y.T. mini taper polygon patented design

- Full range of Y.T. indexable UFO T-slot cutter

- Customized indexable saw blade in dia. 600 mm

- Multi-functional Saw blades

- ndexable UFO MILL

- Chamfer king _ Y.T. indexable countersink max. dia. 110 mm

- Chamfer king _ Y.T. indexable countersink

- How to put insert into the saw blade without any screwing facility?

- What is the difference between two types of side milling cutter in the catalog?

- Does Y.T. have a T-slot for machining work-piece with more than HRC 40°?

- Contact Us Send Inquiry Now

- E-Catalog YT-Catalog Download