Disc Milling Cutter - CW

CW Series

Under sufficient machine horsepower, CW disc milling cutter can directly machine groove in big width and doesn't need several separate processes. Besides, solid CW disc milling cuter is also a good choice if you want to increase machining stability.

Staggered teeth design of insert can effectively reduce machining resistance during removing great amount of metal.

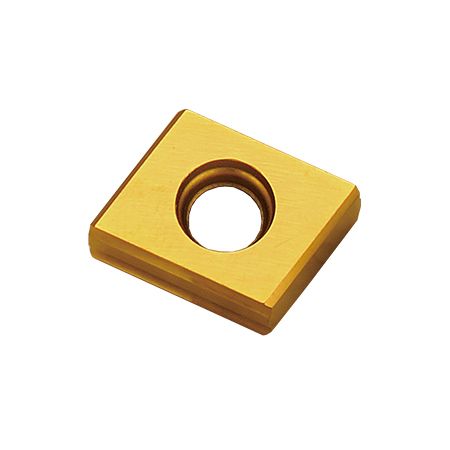

Integral pre-harden steel cutter is equipped with three carbide inserts CNGX 1005 / 1305 / 1605 to increase your efficiency in heavy machining or roughing. Fully grinded G-grade insert provides higher machining precision and insert life as well as better chip evacuation. Special chip evacuation geometry on insert is able to effectively reduce machining resistance and machine loading during rapid material removal.

In addition to customized dimension or cutter / insert design, YIH TROUN's professional R&D team is also engaged in production planning for many well renowned manufacturers and provides customized solution.

Regarding chip evacuation for different work piece material, we design three different insert geometries: E / ME / M

E: In connection with machining of non-metal material.

ME: In connection with material which is hard for machining or machining of cast iron.

M: In connection with machining of steel.

Features

- Unique cutter geometry design to optimize chip evacuation and thus raise insert life and machining efficiency.

- Insert has 4 effective cutting edges.

- Customizable specification.

Specification

- Applicable thickness: 14 - 30 mm

- Cutter diameter of entire series: 80 - 160 mm

- Movies

- Catalogue Download