Mechanical Balance at Its Peak: Y.T. Customized L/R Helix Side Milling Cutter Set – Field Test

This video showcases a tailor-made solution by Yih Troun (Y.T.) for high-precision requirements:

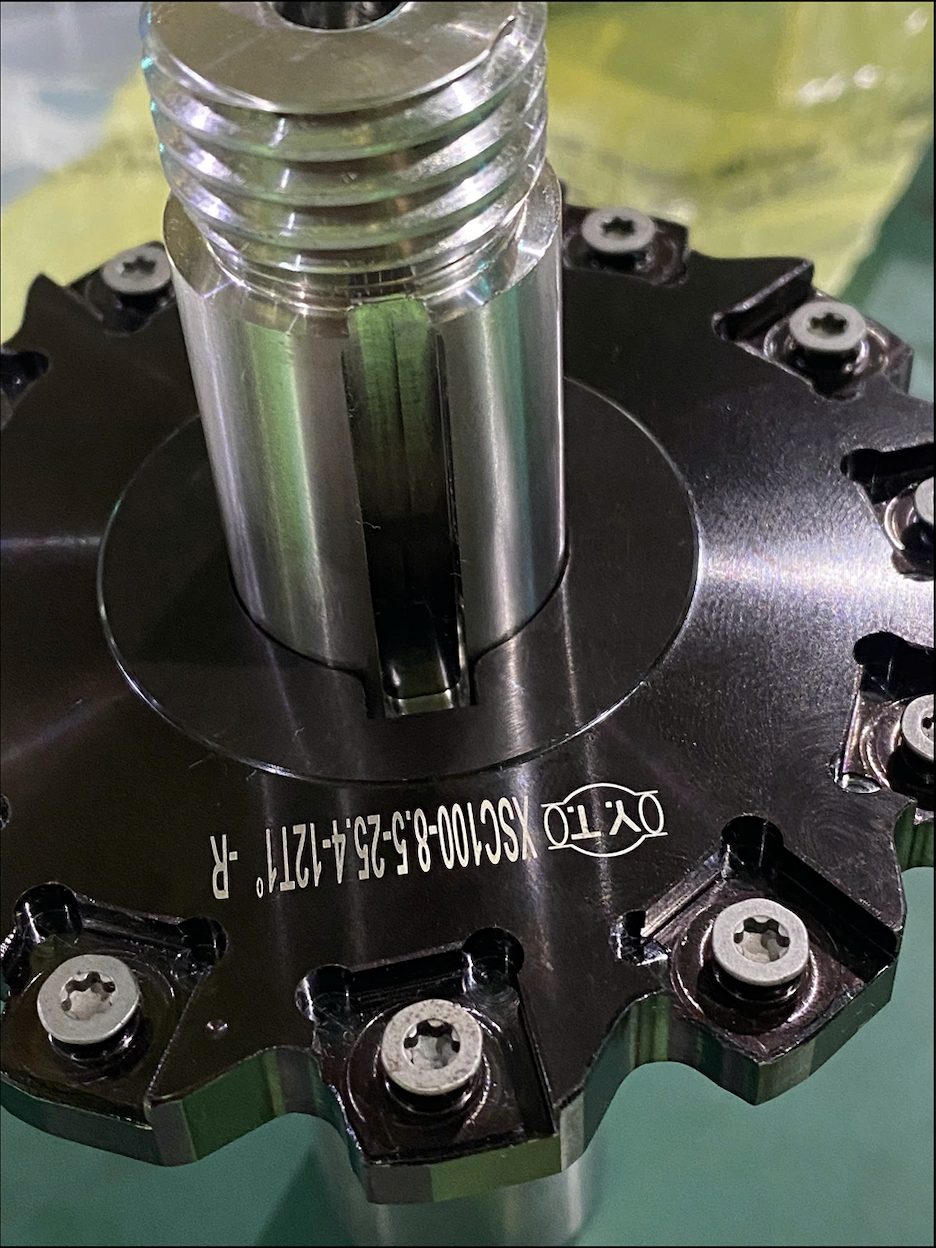

Utilizing the XSC100 Left/Right Helix Cutters (1°-L / 1°-R) to achieve synchronized bilateral machining.

🌟Core Advantages: Mechanical Neutralization (Custom L/R Configuration):

By leveraging the opposing axial forces generated by the left and right helix cutters, cutting vibrations are perfectly canceled out. This ensures zero workpiece deflection and eliminates "tool bouncing."

Doubled Precision: The exclusive 1° back-taper design significantly reduces friction between the tool body and the sidewall, achieving superior verticality and an exceptional surface finish. Efficient Chip Evacuation: The symmetrical spiral paths allow chips to be rapidly discharged to both sides, preventing heat accumulation and extending insert tool life.

Test Data: Cutter Body: XSC100-8-25.4-12T 1°-L & 1°-R (Customized Edition)

Insert: SNGX1203VIT1-ME Parameters: S350 (m/min) / F200 (mm/min)

Summary: Synchronized bilateral cutting is not just about doubling efficiency; it is a professional solution that solves complex machining challenges through the mastery of "Mechanical Balance."

Youtobe: https://youtu.be/FHJ3ao7B3ak