Indexable UFO Family Series

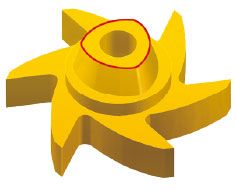

UFO family is YIH TROUN’S innovative patented product, the name derived from its tapered-polygon structure looks like the shape of UFO space ships.

The tapered-polygon design gives a greater capacity to withstand the cutting torque and transmit shaft power, it assures the shaft do synchronous drive the shank and insert at the same speed and position. The tapered-polygon insert is made by complete-grinded processing to keep the tolerance of connect positioning in ±0.01mm and optimize feed speed and insert life.

Furthermore, the tapered-polygon design provides a simple connection and easily transfer between different inserts and shanks, it helps to lower cost and save space for keeping stock of sufficient cutters.

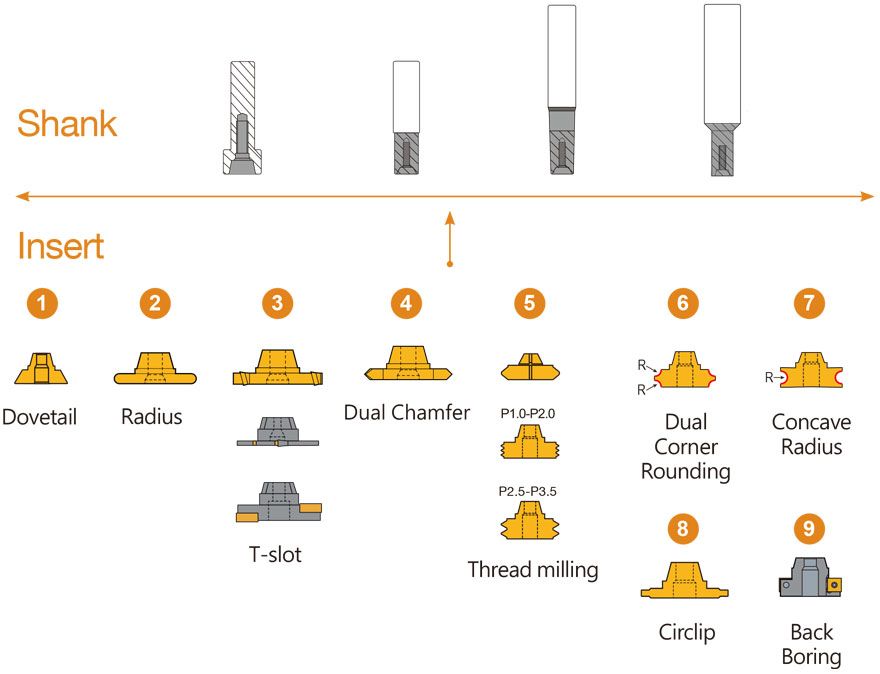

Each solid-type cutter is available in one size and single application only. YIH TROUN UFO family use patented tapered-polygon design, it serves a simple connection to various types of UFO inserts, such as: T-Slot Inserts、Thread Milling Inserts、Dual Chamfer Inserts、Dual Corner Rounding Inserts、Radius Grooving Inserts、Dovetail Inserts、Circlip Inserts、Concave Radius Inserts、Gear Groove Inserts and different kinds of customized Inserts …etc. Each of the unique shank is suitable for minimum 400 inserts of UFO series. With total 6 shanks of entire CAPTO range, it is applicable to more than 1400 UFO inserts.

To support a wide application range, YIH TROUN provides many optional sizes of shank in different diameters and lengths. Apart from HSS shanks, we also offer carbide shanks which conduce to a greater stability for long deep overhang machining.

-

UFO Profile Insert

The special profile series of UFO inserts are designed for machining on small-diameter applications, with 6 different types in various angles and forms. They are UFO radius insert, UFO dual corner rounding insert, UFO dual chamfer insert, UFO dovetail insert, UFO concave radius insert, and UFO circlip insert, applied to different angles for various special machining, with every insert fitting to the UFO series T-slot shank CB3 and CB3W.

-

UFO Thread Milling Insert

YIH TROUN UFO thread milling insert uses CNC milling program to machine threads in a spiral approach. The thread milling insert with multi-tooth design provides high machining efficiency, it comes with full-profile inserts / partial profile inserts and small-diameter solid carbide thread milling, with the angles expressed in both imperial and metric units. The partial profile insert is a single pitch with multiple (4-6) teeth design for low resistance and high efficiency, same insert can produce different pitch and thread size. One single insert can complete the machining of a variety threads such as internal threads, external threads, pipe threads RC / NPT. The UFO thread milling insert is the best choice for even machining large-size threads on a small machine, or when high precision threads are required. The partial profile insert handles dozens of thread sizes, and when a workpiece needs different thread sizes, a single insert can get the job done in one go with minimum change of insert and no need of taps. The full profile insert is designed with (2-3) pitches and multiple (4-6) teeth. Its machining resistance is much lower than the thread milling insert in multiple pitch but single teeth design which available in the market, and therefore gives higher efficiency and longer tool life. The tap is mostly the fastest with most absolute sizes, but sometimes requires multi-diameter long in thread length or faces difficulties in machining large-size threads due to insufficient power of the machine. The UOF thread milling insert offers the best solution, with small machining resistance, high thread precision, and adjustable thread sizes. The full series offer pitch angles of 55° and 60°, along with the full profile and partial profile standard inserts in diameters of Ø 10, Ø 12, Ø 15, Ø 20, Ø 25. For application programs, please see the catalog examples on various threads.