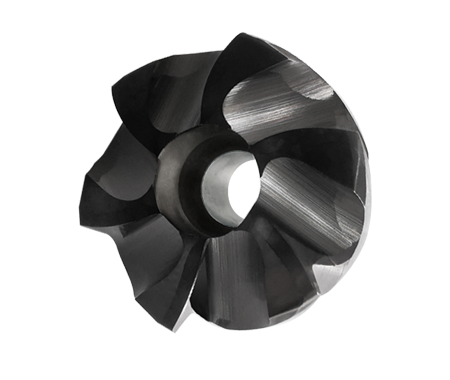

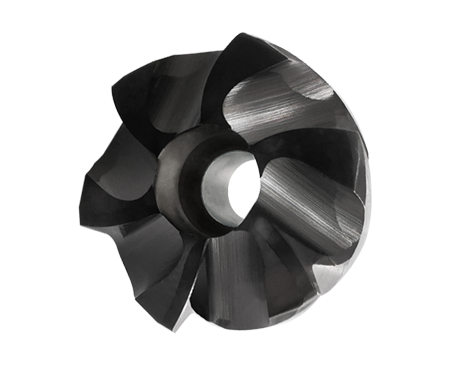

UFO MILL High Feed Mill - 3BH

3BH Series

UFO high-feed milling head 3BH series with 4, 5, 6, flutes and unique design of arc and point contact. It is effective in keeping the radial force lesser than axial force. The cutting force is transferred to the spindle, it brings machining process in stable conditions and carries out a high removal rate. A variety of special cutting angles can reach 3 times the speed of other milling tools while milling, and the ultra-high milling feed can greatly reduce the machining time and optimize the value.

Advantage:

1. The patented CAPTO positioning design further improves the tightness and stability of the tool holder and the milling head.

2. The special geometric design reduces friction and leads to an efficient high feed machining.

3. Suitable for a wide range of applications in aerospace, medical and automotive industries.

4. Fully grinded carbide head achieves excellent tool life

5. UFO high feed’s multi-flutes and arc design achieves 3 times faster than ordinary milling tool.

Features

- Roughing and finishing can be done in one step.

- Special chip breaking geometry

- Multiple flutes achieves faster feeding rate

- This high-efficiency tool achieves up to 3 times high-feed mode

- The design of indexable milling head greatly reduces the waste of rare earth resources.

- Different carbide heads can be matched with different HSS/ carbide shanks to maximize flexible application

- Patented taper polygon positioning design, which can be automatically and precisely positioned. The milling head can be replaced directly on the spindle for saving tool calibration time

- Applications: face milling, grooving, high-feed in roughing and finishing, r-angle machining at the bottom of pocket milling

Specification

- UFO MILL head diameter: Ø10-Ø13、Ø16-Ø17 、Ø20-Ø21、Ø25mm

- The corner radius: R0.6, R0.8

- Effective no. of machining flutes: 4, 5, 6 flutes

- Applicable machine tool: CNC milling machine

- Available in customized sizes and shapes(max. outer diameter Ø25mm)

- Suitable for: Steel, Stainless steel, Titanium Alloys

- Movies

- Catalogue Download

-