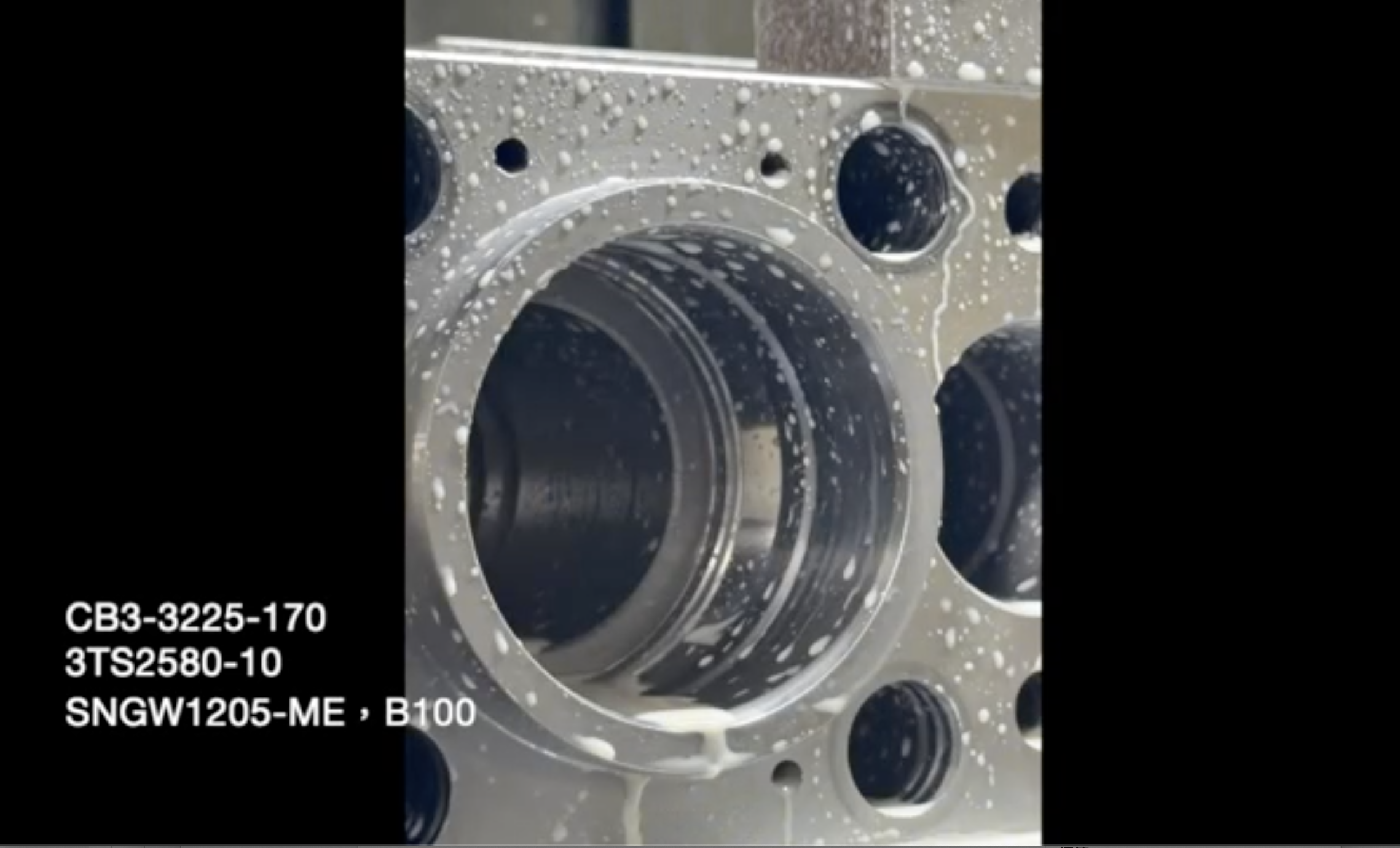

【Technical Case Study】Optimizing Bore Machining Efficiency: Y.T. UFO Series Field Test

In the machining of large components, balancing efficiency with surface quality is a core technical challenge.

This case study demonstrates the Y.T. (Yih Troun) UFO Modular Series performing cutting operations on large-diameter bores.

🛠 Tooling Configuration:

* Shank: CB3-3225-170

* Cutter Head: 3TS2580-10

* Insert: SNGW1205-ME, B100

📋 Field Observations

1. Machining Stability: The video demonstrates the tool's vibration control during deep-hole entry.

The modular interface design maintains rigidity during high-speed cutting.

2. Chip Evacuation & Cooling: When paired with proper coolant delivery, the SNGW insert geometry effectively minimizes the risk of chip accumulation within the bore.

3. Surface Finish: The latter part of the video shows the post-machining condition of the bore wall, achieving a surface finish that meets standard tolerances for industrial mechanical components.

youtobe: https://youtu.be/pe2yZtZ8WY8